Project No. 11

WL Engine Rebuild & Tuning

|

It all started when Steve came to me and told me that his son needs a school project and he likes to rebuild an engine. He asked me whether I have an old engine that needs some rebuild. I sure do, was my answer. I had the rotten WL engine sitting in my garage for quite a while. It was a cheap buy on e-bay and

it was sure in a bad contition. The right thing for a school

project:-) |

|

|

|

| The Rebuild |

|

| After cleaning the rebuild can begin. The cases needed some new races and they had to be lapped in. |

|

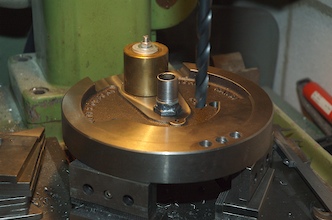

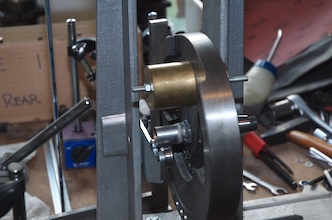

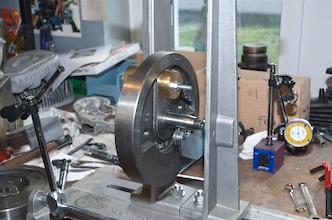

I still decided to buy new ones and since we do that we should get some stroker ones! Victory Library sells a whole variety of stroker flywheels for 45's. We got the 4-7/16" this results in 861cc with STD pistons. A set of new connecting rods, new shafts and crank pin were used. Next step is the balancing

of the crank: |

|

|

|

|

|

|

|

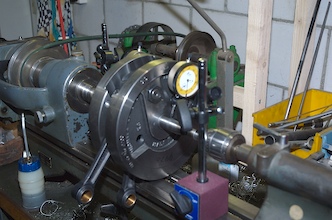

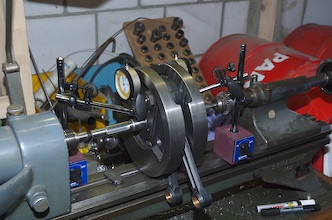

55% was used as balancing factor. After both wheels are balanced the crank shaft can be assembled and trued. I use my old Schäublin 102 lathe to do so. |

|

|

|

|

|

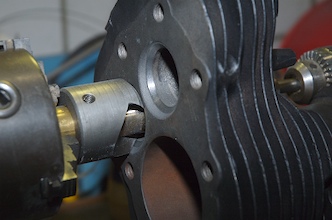

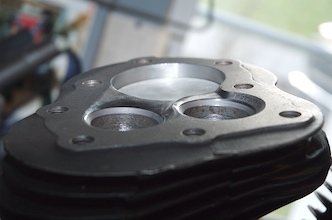

Because of the longer stroke the clearance between rods, cases and cylinders has to be checked and material needed to be removed....

.... on cases and

cylinders |

|

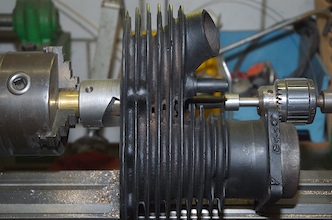

The cylinders needed new seats for the valves. The Schäublin can be used for this job as well. |

|

|

|

Since we have more stroke now, why not doing some more to enhance power. A deck relieve adds the most (nice pictures of relieved cylinders can be found on www.beautyofspeed.com.

All the blue area has to go to

give better flow. |

|

|

|

|

|

|

|

|

Also all the ports and the manifold where reliefed and cleaned. |

|

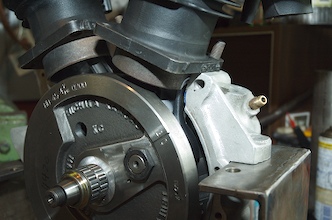

The cylinders are bored to 0.070" over and stroker pistons from Victory Library where used. With the bigger stroke this results in 905cc (55.23") |

|

| Done: quite a difference from the initial state;-) |  |

| And in the bike: She is running very well!!

If you like to comment on this project you can visit my post on the Flathead Power Tech Talk |

|

|

|

.jpg)